INFORMATION TECHNOLOGY ENGINEERING

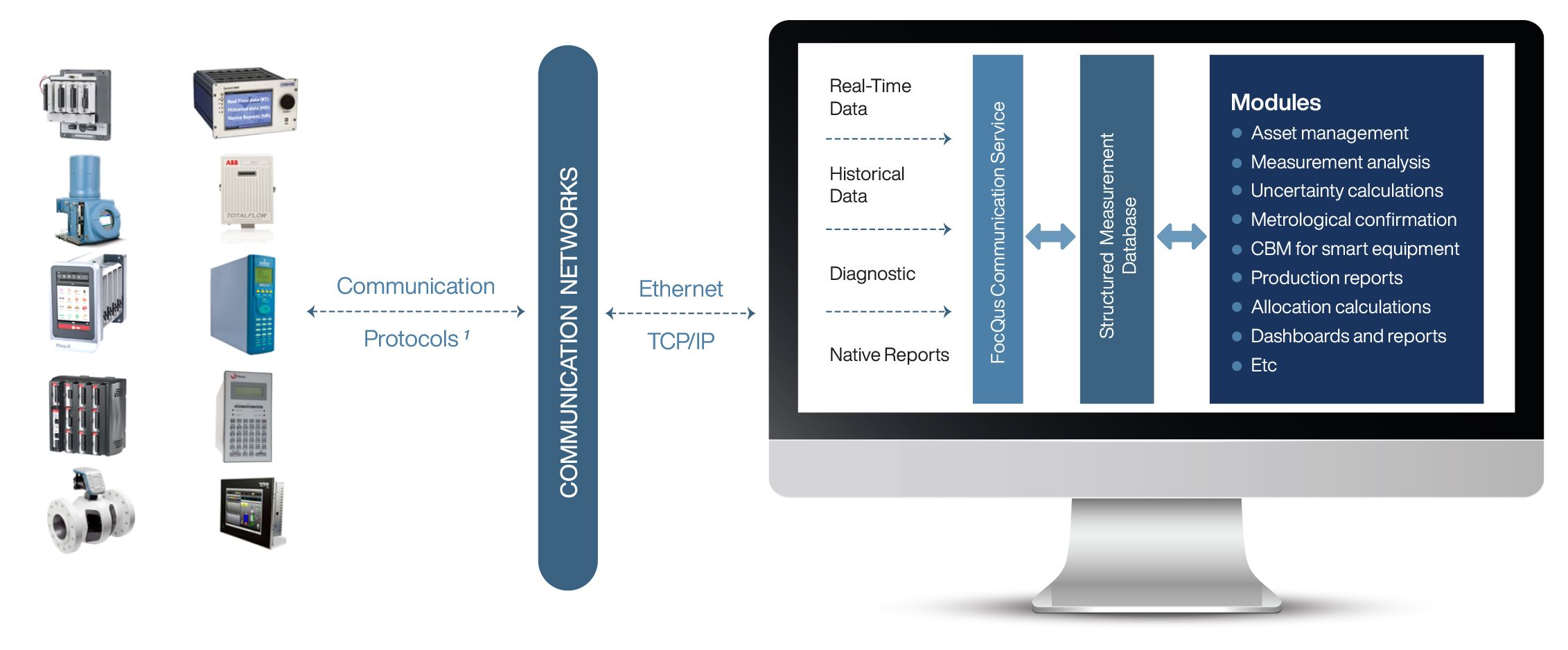

We provide integral management of measurement information, keeping all types of data securely stored and fully traceable within a structured metering database. This ensures that information is always available to support auditing, regulatory compliance, and timely decision-making.

We develop and implement solutions that allow collection, validation, analysis, and reporting of raw flow data coming from the operational field. By using advanced algorithms and procedures we assure an error-free and structured metering data base.

Measurement Management Process Design

Designing structured processes for measurement, analysis, and reporting to ensure reliable data flow, standardized methods, and continuous performance improvement.

Database Architecture

Designing a robust database framework for seamless measurement data integration, synchronization, and secure storage to ensure consistency and accessibility across all systems.

Data Security

Implementing strong encryption, secure communication channels, and strict access control with authentication, supported by regular audits and continuous monitoring to protect data integrity and confidentiality.

Communication Networks

Integrating automation and business systems through tailored communication protocols and optimized network architecture to enable seamless, reliable, and efficient data exchange.

Application and Information Integration

Connecting SCADA systems, process historians, SAP, Maximus, and client business intelligence platforms to ensure seamless data exchange, unified insights, and optimized operational performance.

Cloud Integration

Leveraging cloud technologies for scalable and flexible solutions that enable centralized data management, seamless API connectivity, and full interoperability across platforms and applications.

Measurement Data Management

We provide integral management of measurement information, keeping all types of data securely stored and fully traceable within a structured metering database. This ensures that information is always available to support auditing, regulatory compliance, and timely decision-making.

FIELD DATA COLLECTION

Raw Database

DATA VALIDATION

Validated Database

MEASUREMENT ANALYSIS

Measurement Database

DASHBOARDING AND REPORTING

Reporting Database

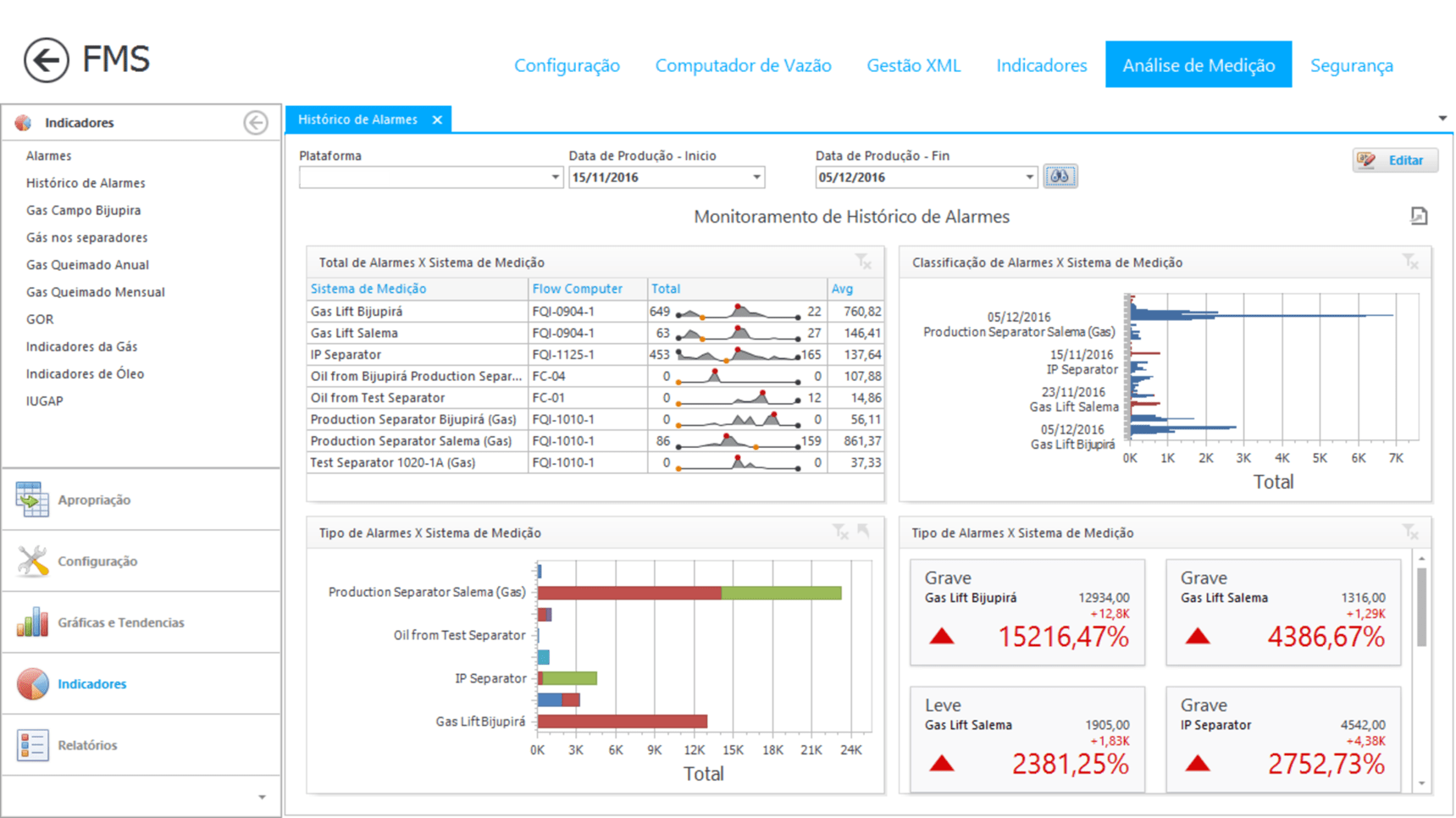

Flow Management System (FMS)

Integral and total Management of Measurement Processes

Flow Management System (FMS)

Integral and total Management of Measurement Processes

The Flow Management System (FMS) is an intelligent platform that transforms raw measurement data into actionable insights, enabling reliable monitoring, analysis, and decision-making across flow and gas measurement systems.

FMS performs the following tasks:

- Collects measurement data from smart equipment and IT systems.

- Validates collected data using statistical methods and machine learning algorithms.

- Implements Condition-Based Monitoring (CBM) for flow meters and gas analyzers.

- Configures and parameterizes flow computers and flow meters.

- Monitors and records configuration changes in smart equipment, with alerting capabilities.

- Performs measurement analysis and validation using API, AGA, and ISO standard algorithms.

- Executes advanced mathematical calculations for flow management.

- Efficiently manages equipment events and alarms.

- Provides trending graphics for data visualization.

- Produces automated reports and interactive dashboards for distribution to stakeholders, including regulatory authorities.

- Delivers alarms, failure alerts, and tailored reports to relevant departments and personnel via SMS and email.

- Manages measurement failures from detection to resolution, tracking timelines and calculating key metrics such as Mean Time to Repair (MTTR) and Mean Time Between Failures (MTBF)

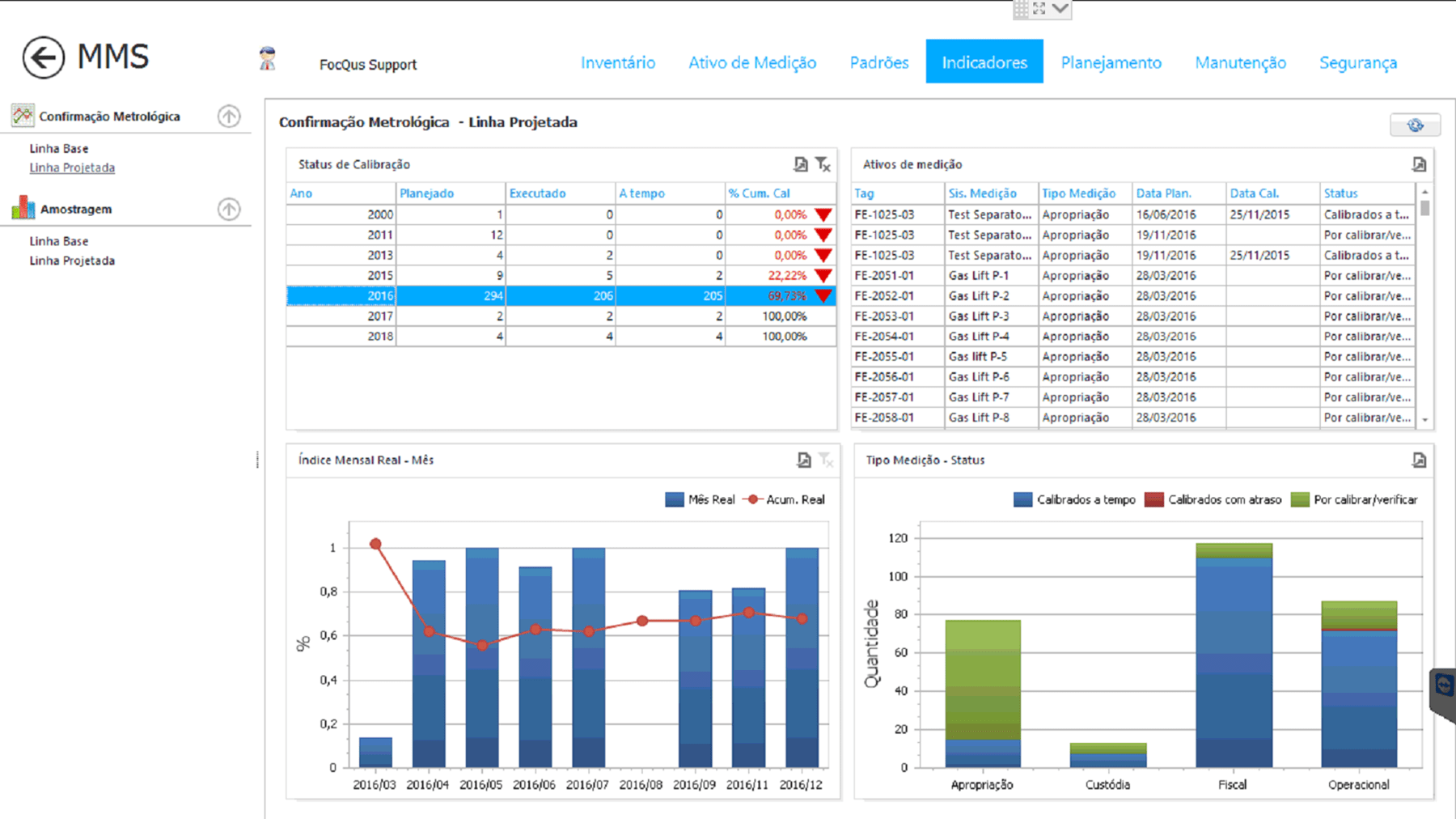

Metering Management System (MMS)

Integral and total Management of Measurement Processes

Metering Management System (MMS)

Integral and total Management of Measurement Processes

The Measurement Management System (MMS) ensures accurate, reliable, and compliant measurement by managing assets, verifying systems, planning and coordinating operations, calculating flow and fluid properties, supporting production allocation, and delivering actionable insights through dynamic reporting.

MMS performs the following tasks:

- Supports the execution of operational and metrological processes in full compliance with ISO 10012 requirements.

- Manages measurement assets, including metering facilities and equipment.

- Performs metrological confirmation and verification of metering systems and instruments.

- Plans and coordinates operational activities related to metering and measurement.

- Calculates flow rate uncertainties in real time or on demand.

- Determines fluid properties and their associated uncertainties with high accuracy.

- Conducts well test evaluations and performance analyses.

- Executes product allocation calculations to ensure accurate production accounting.

- Manages and reconciles tank farm inventories.

- Recalculates volumes and energy values under varying operational conditions.

- Generates detailed metering and production reports for operational and regulatory purposes.

- Monitors measurement deferments and supports timely resolution.

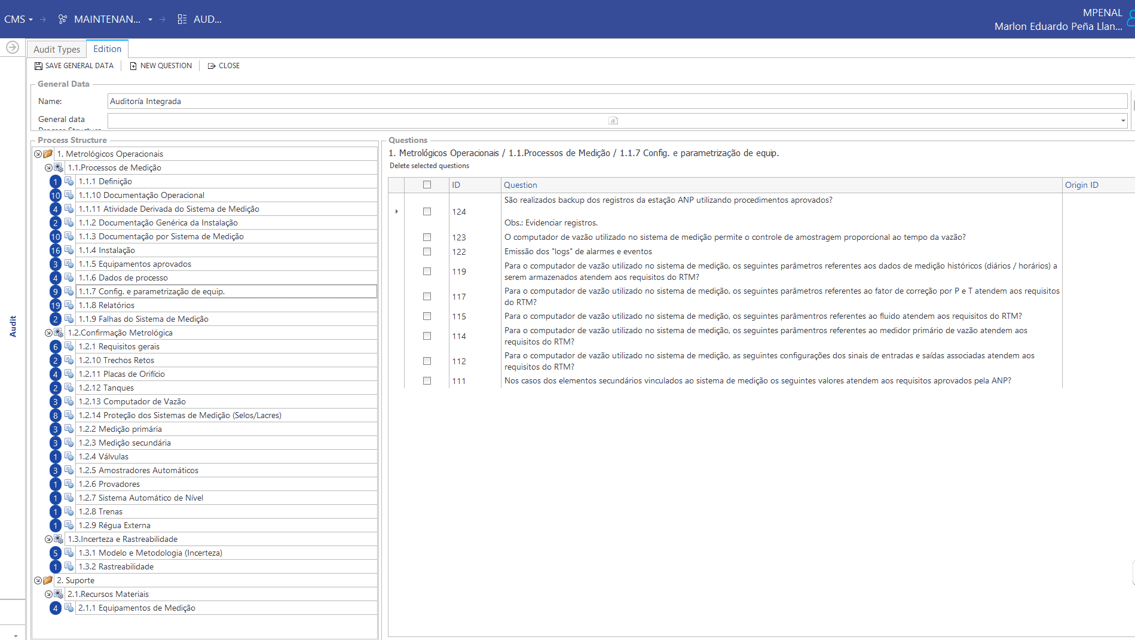

Compliance Management System (CMS)

Integral and total management of measurement Processes

Compliance Management System (CMS)

Integral and total management of measurement Processes

CMS manages audit programs to assess compliance with internal and external requirements. It supports all key stages of the audit process, including setup, resource planning, execution, non-conformity management, action plan development, and closure.

CMS performs the following tasks:

- Defines the processes to be audited.

- Identifies clients and production assets subject to audit.

- Establishes Q&A criteria and weighting for each audited process.

- Develops audit indicators based on audit results.

- Assigns roles and responsibilities to personnel involved in the audit process.

- Schedules audits according to audit type.

- Customizes and finalizes the audit scope.

- Executes the audit.

- Reviews, approves, and communicates results to stakeholders.

- Issues and documents audit results.

- Compiles and manages lists of non-conformities.

- Defines corrective action plans, including responsibilities, timelines, and required resources.

- Monitors the implementation of corrective actions.

- Provides notifications and updates to all stakeholders.

- Closes the action plan upon completion

We integrate the metering database with different data client applications to ensure accuracy and traceability of processes executed in other operational and/or supporting areas. We develop integrated applications for use throughout the entire business value chain

Oil & Gas Integrated Solutions

Tailor-made client solutions

From niche solutions

Development of management solutions to integrate Measurement related areas in Upstream Oil & Gas sector (exploration and production).

To integrated solutions

Development of management solutions spanning operations across the entire Oil & Gas Value Chain (Upstream, Midstream and Dowstream).

Technical Support

24/7 multi-channel (phone, e-mail, remote, website)

Reliable, credible, proactive and high quality

Commitment and dedication to problem resolution

Personnel well trained, qualified and knowledgeable

Incidents solved in-time and within SLAs.

Website to track incidents resolution

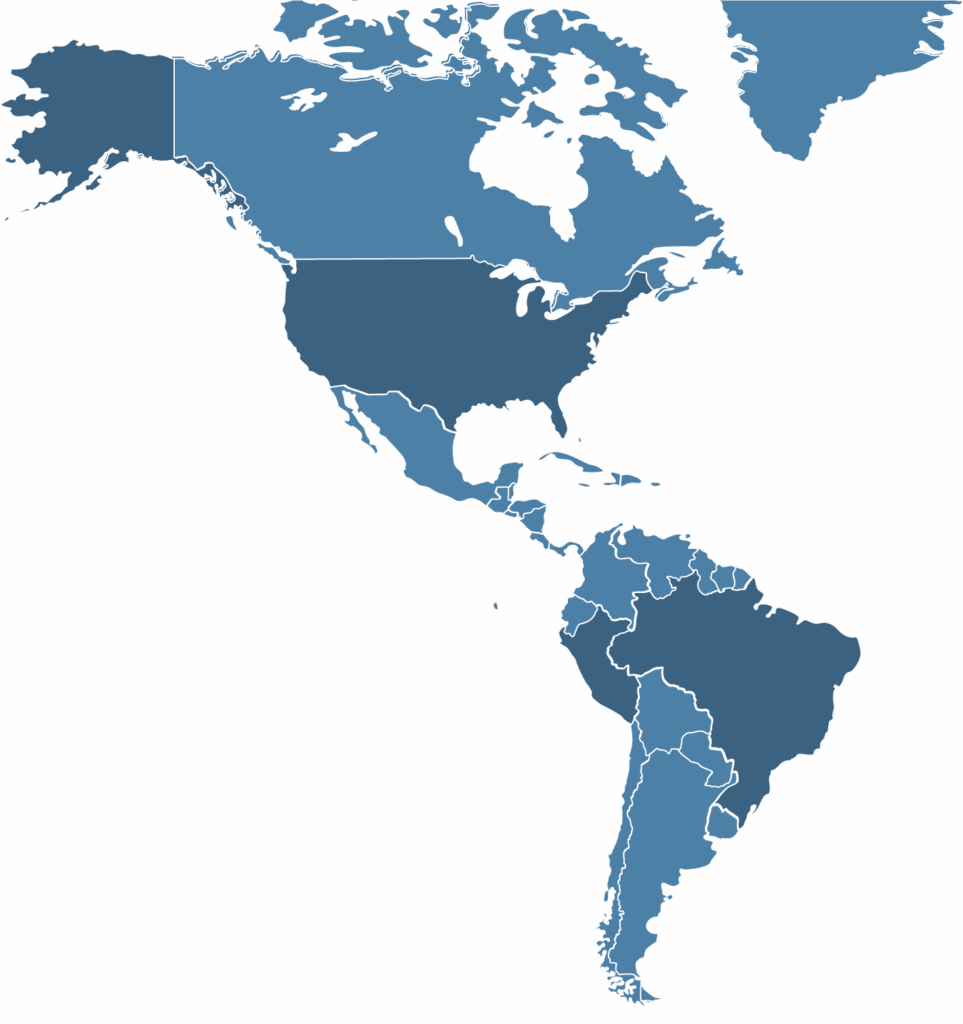

United States

Brazil

Peru

Where are our solutions installed?

Main location and clients

10

Onshore Production Assets

21

Offshore Production Units

01

Biggest Natural gas pipeline

> 50

FMS & MMS installed

> 700

Complete Metering System

> 5700

Measurement equipment